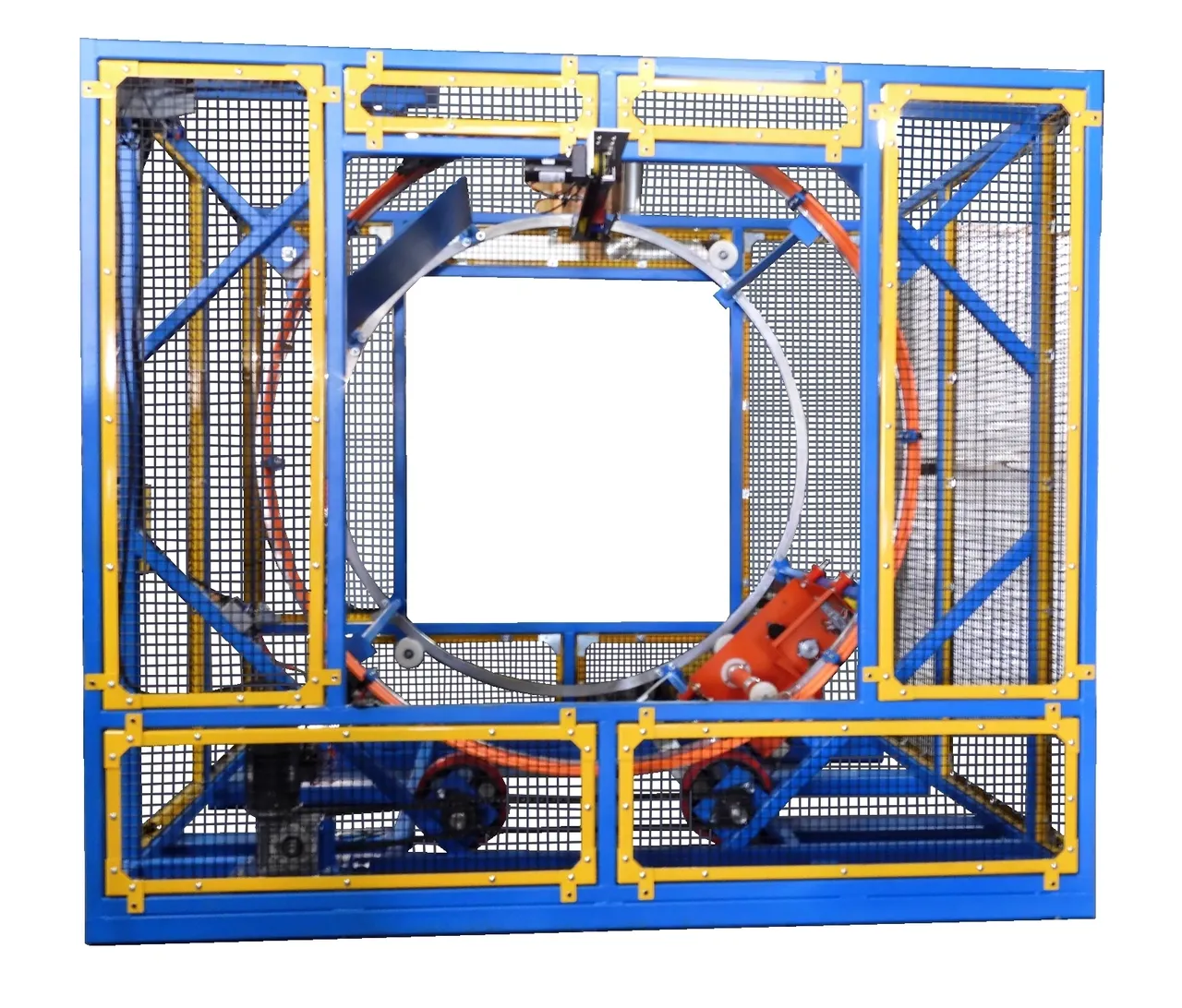

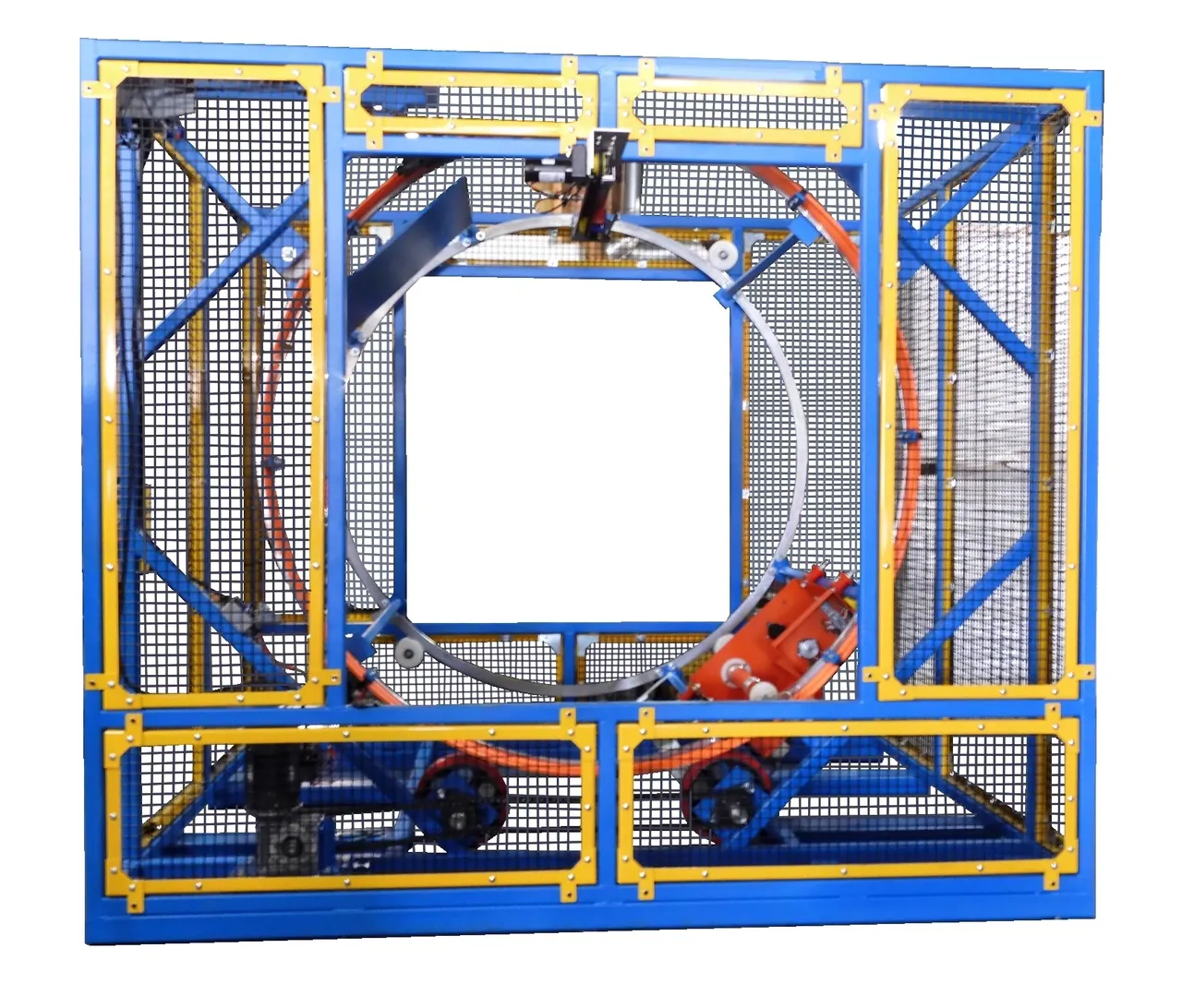

FPS 3000FT Forklift Orbital

FAST, EASY, SAFE.

Your operator drives your product into the centre of the machine, starts the cycle, and the FPS Forklift Orbital does the rest.

Scroll down to learn more...

HOW DOES IT WORK?

Let's get down to business...

Your forklift operator drives the load into the centre of the machine and starts the wrap cycle from a remote or lanyard.

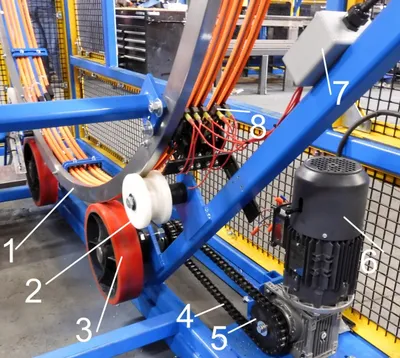

The film carriage then travels on two support tubes, which are attached between the two rings. A chain attached to the film carriage, driven by a gearbox motor combo, pulls the carriage forward and back across the load. Carriage limits prevent mechanical over-travel. As the rings rotate, the carriage travels back and forth, enveloping the load with film. Once the cycle is completed, the film is automatically cut and wiped to the load.

Ready for delivery!

VIDEO

TELL ME MORE

FPS3000FT VS. THE COMPETITION

Our Competitors

- Most all wrappers are manual.

- The fork truck operator must get off the truck, manually attach the film to the skid, start the ring turning, and then push the whole machine manually forward and backward. This is a huge loss of time to wrap each load and an unnecessary risk of injury to the operator.

- Another type is automatic, but the fork truck operator must move the fork truck backward to wrap the load length. There could be a hazard if the operator does not see passing traffic.

Fox FPS3000FT

- Reduces lost time or repetitive injuries to employees

- Fully automatic; no need to attach or cut the film

- No air is required to operate the film clamp/cutter

- No need to move the fork truck while the product is wrapped

- It takes ½ the time to wrap a load

- Requires 115V/15A dedicated wall outlet or a plug with no other equipment plugged in

Load Capacity

Height: 48"

Width: 48"

Length: 48" standard with the possibility to wrap longer products

Weight: Dependent on forklift manufacturer specifications

SPECIFICATIONS

Detailed Specs

Control

Ring

Film carriage

Remote Control Start/Stop Wrapper

DOWNLOADS

FPS3000FT INTRODUCTION (docx)